YTH Тип Моторбарабан (моторизированный шкив)

с вынесенным редуктором (Приводной шкив)

Описание продукции

Этот продукт производится по технологии, импортированной из Германии. Он обладает следующими преимуществами: закалённая поверхность зубьев шестерен, планетарный редуктор, стабильное вращение, низкий уровень шума, высокая перегрузочная способность и широкий диапазон мощностей. Может быть укомплектован гидродинамической муфтой, устройством защиты от обратного хода, тормозом и взрывозащищённым электродвигателем. Подходит для крупных и средних ленточных конвейеров, работающих в тяжёлых условиях и требующих взрывозащиты.

YTH Тип Моторбарабан (моторизированный шкив)

с вынесенным редуктором (Приводной шкив)

Описание продукции

Этот продукт производится по технологии, импортированной из Германии. Он обладает следующими преимуществами: закалённая поверхность зубьев шестерен, планетарный редуктор, стабильное вращение, низкий уровень шума, высокая перегрузочная способность и широкий диапазон мощностей. Может быть укомплектован гидродинамической муфтой, устройством защиты от обратного хода, тормозом и взрывозащищённым электродвигателем. Подходит для крупных и средних ленточных конвейеров, работающих в тяжёлых условиях и требующих взрывозащиты.

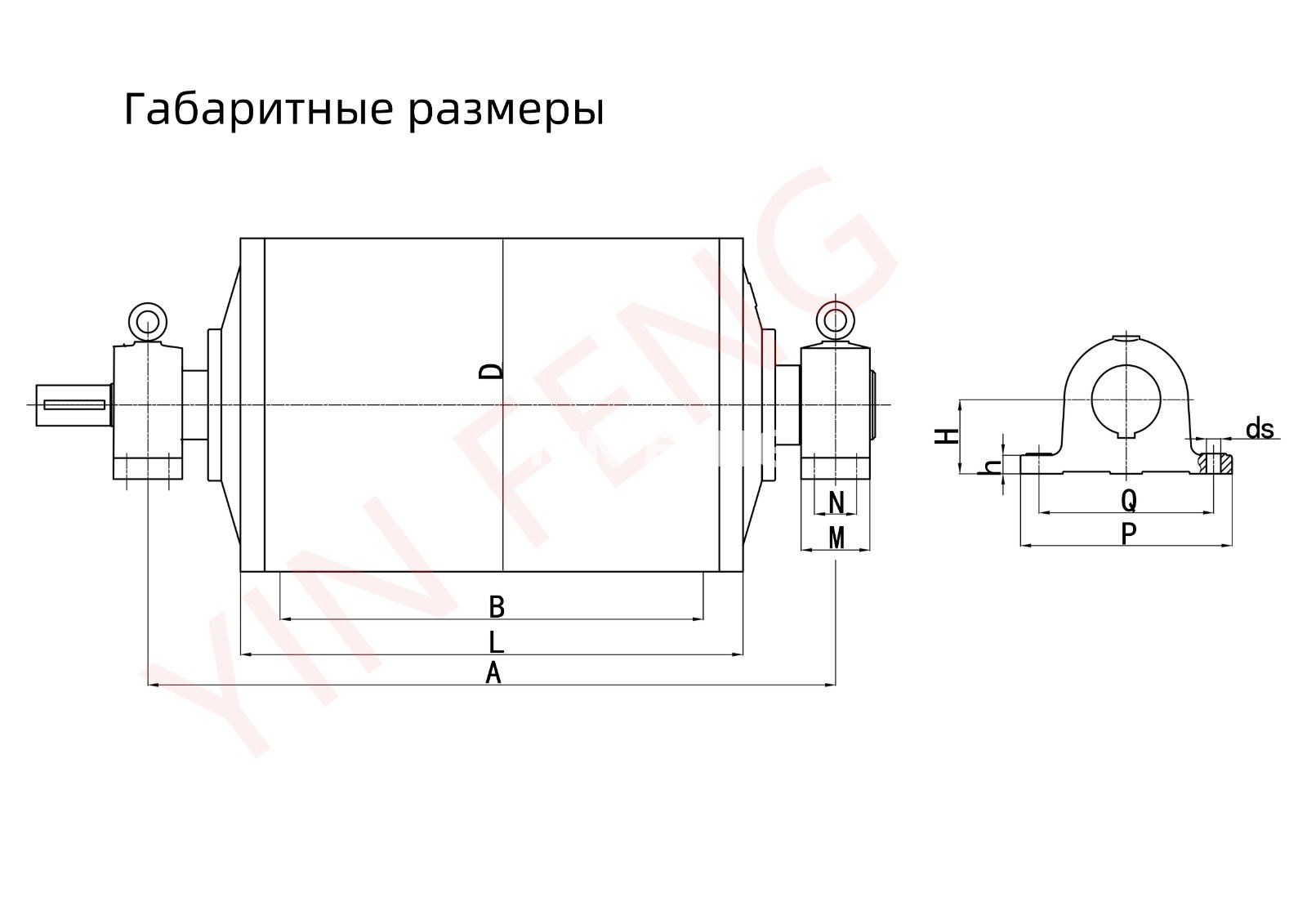

Мотор-редукторный приводной барабан модели YTH состоит из трёх частей: корпуса барабана, привода и кронштейна электродвигателя (модель II без кронштейна). Корпус барабана включает в себя обечайку, опоры и редуктор. Привод состоит из электродвигателя, муфты, гидродинамической муфты, устройства защиты от обратного хода, тормозов и т.д. Кронштейн изготавливается по чертежам заказчика, сварен из конструкционной стали и служит для установки электродвигателя и кожуха.

Фотографии

Упаковка